Technical

Bolting

Technical Bolting Services for Leak-Tight, Code-Compliant Pressure Boundaries

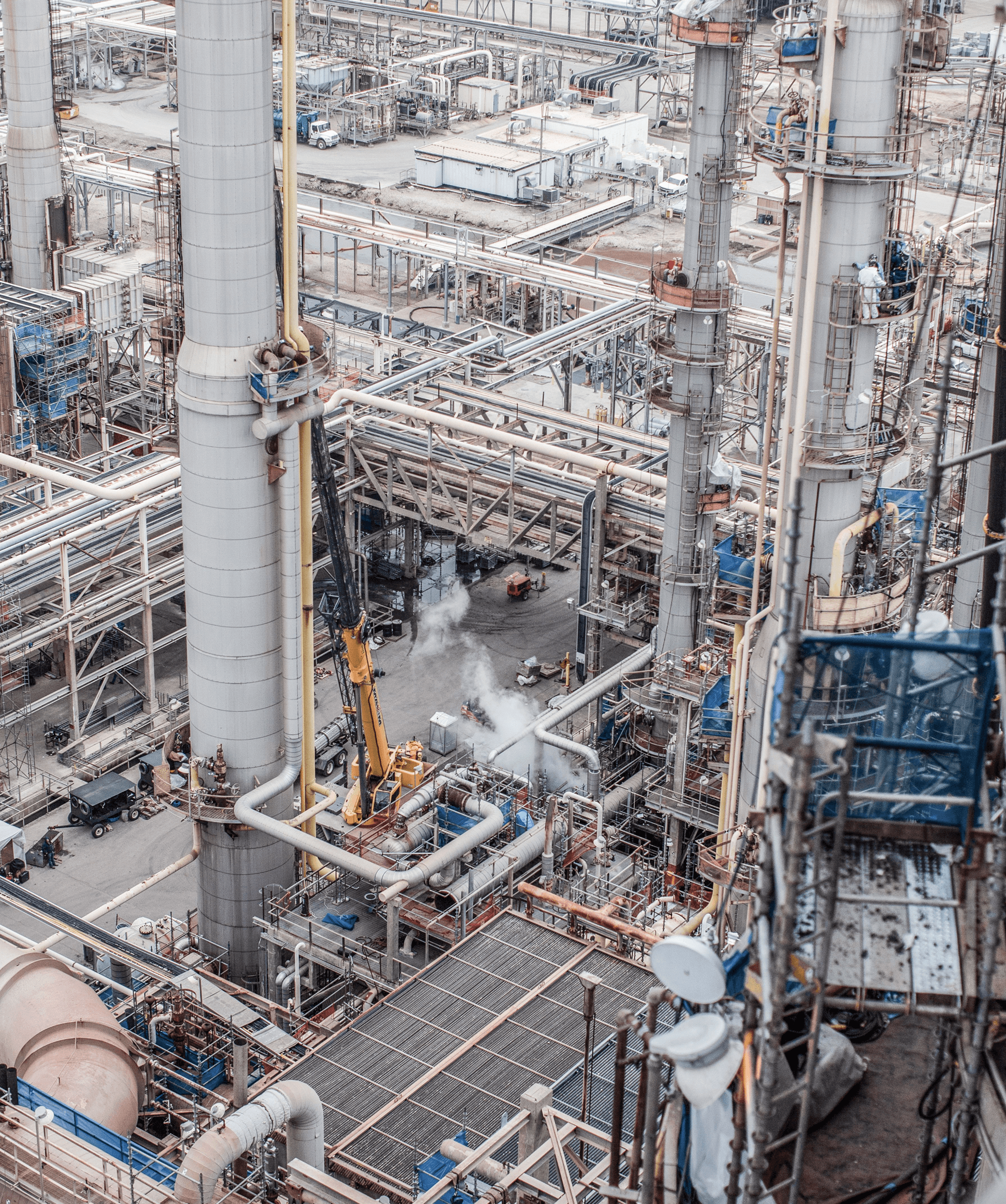

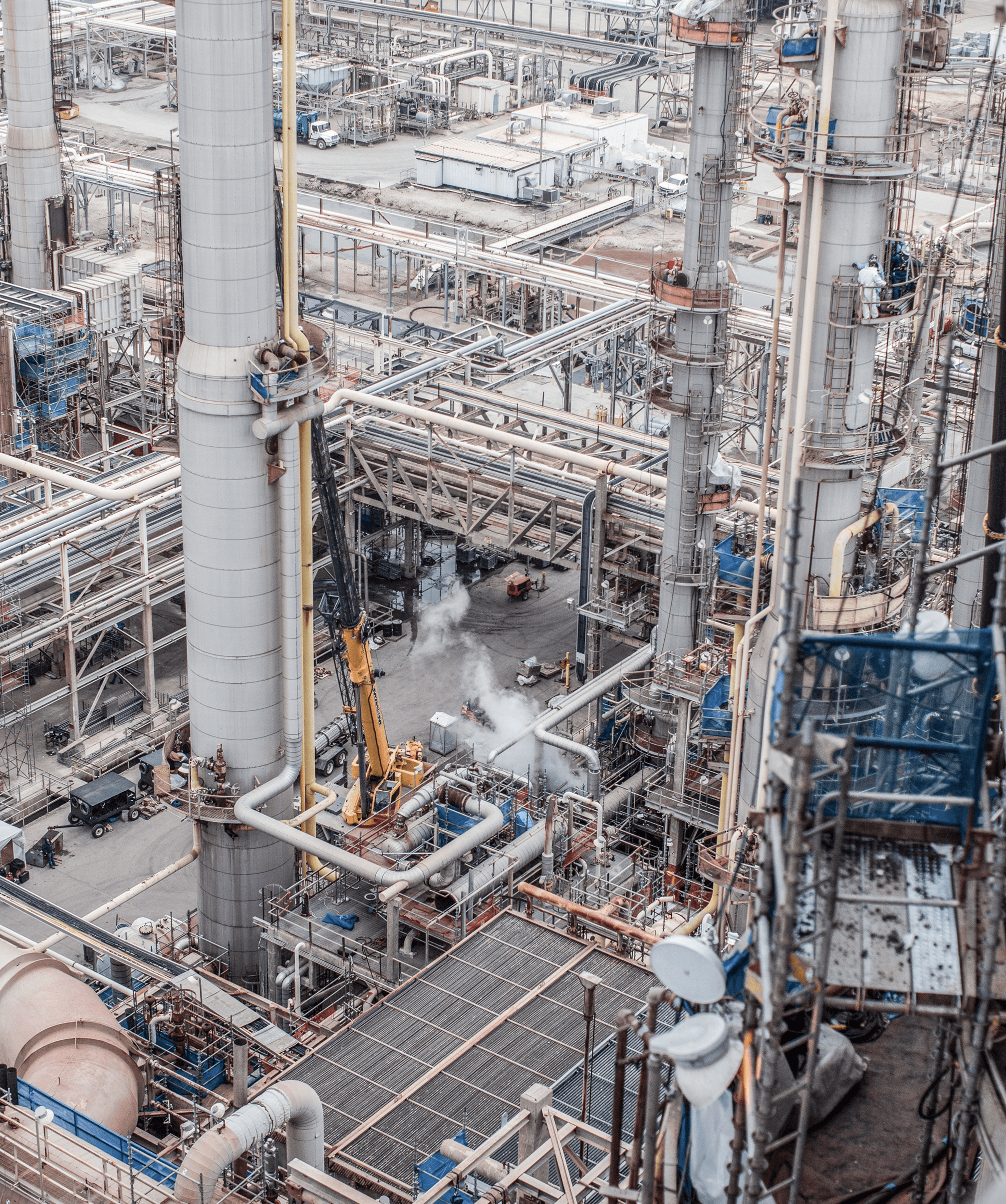

Chronic flange leaks, rework, and start-up surprises can derail even well-planned outages. Our technical bolting crews focus on assembling and verifying critical joints so they start up tight, stay tight, and support your mechanical integrity and performance goals. With trained technicians, calibrated tooling, and controlled procedures, we help you reduce leaks and avoid unplanned interventions so your crews can focus on running the plant, not chasing problem flanges.

Whether you are planning a major outage, addressing problem flanges, or supporting new construction, we bring the same discipline to every bolting scope. The result is fewer surprises at startup and less rework hanging over the schedule when units return to service.

How We Plan and Execute Technical Bolting Work

For each work scope, we align with your operations, maintenance, and inspection teams to understand priorities, access constraints, and schedule drivers. Our crews plan torque sequences, tool selection, and verification steps around your procedures and applicable codes so bolting work supports both safety and production goals.

Using documented methods, calibrated torque and tensioning equipment, and clear sign-off checkpoints, we help you control variation in assembly practices and improve flange performance across multiple cycles and outages. That structure supports smoother startups, cleaner performance, and better long-term mechanical integrity.

Key

Services

- Technical Bolting Services

- Advanced Torque Services

- Critical Flange Tensioning

- Bolt and Gasket Evaluation

- ASME PCC-1 Procedures

- Flange Management Programs

- Ultrasonic Bolt Verification

- Chronic Leak Troubleshooting

- Pressure Test Support

- Inspection and Engineering Coordination

- Integrity QA/QC Records

- Bolting Practices Training

Applications

From piping flanges and vessel nozzles to exchanger channels and rotating equipment, our technical bolting teams support leak-tight, code-aligned joints across projects, outages, and everyday operations.

Industries

We Serve

Our technical bolting expertise supports

a wide range of sectors.

Why UPS Industrial?

One team, one trusted partner. From concept through maintenance or major turnaround, we provide end-to-end solutions.

We understand how to execute work safely while maximizing uptime, controlling costs, enhancing reliability, and driving operational excellence. That integration means fewer hand-offs, better coordination, faster execution, and fewer unknowns.

Let's Talk About Your Technical Bolting Needs

Our technical bolting services can help you improve flange performance, cut down on rework, and keep units running safely between outages. Schedule a walkthrough or talk with our team about your next outage or project.

CONTACT US