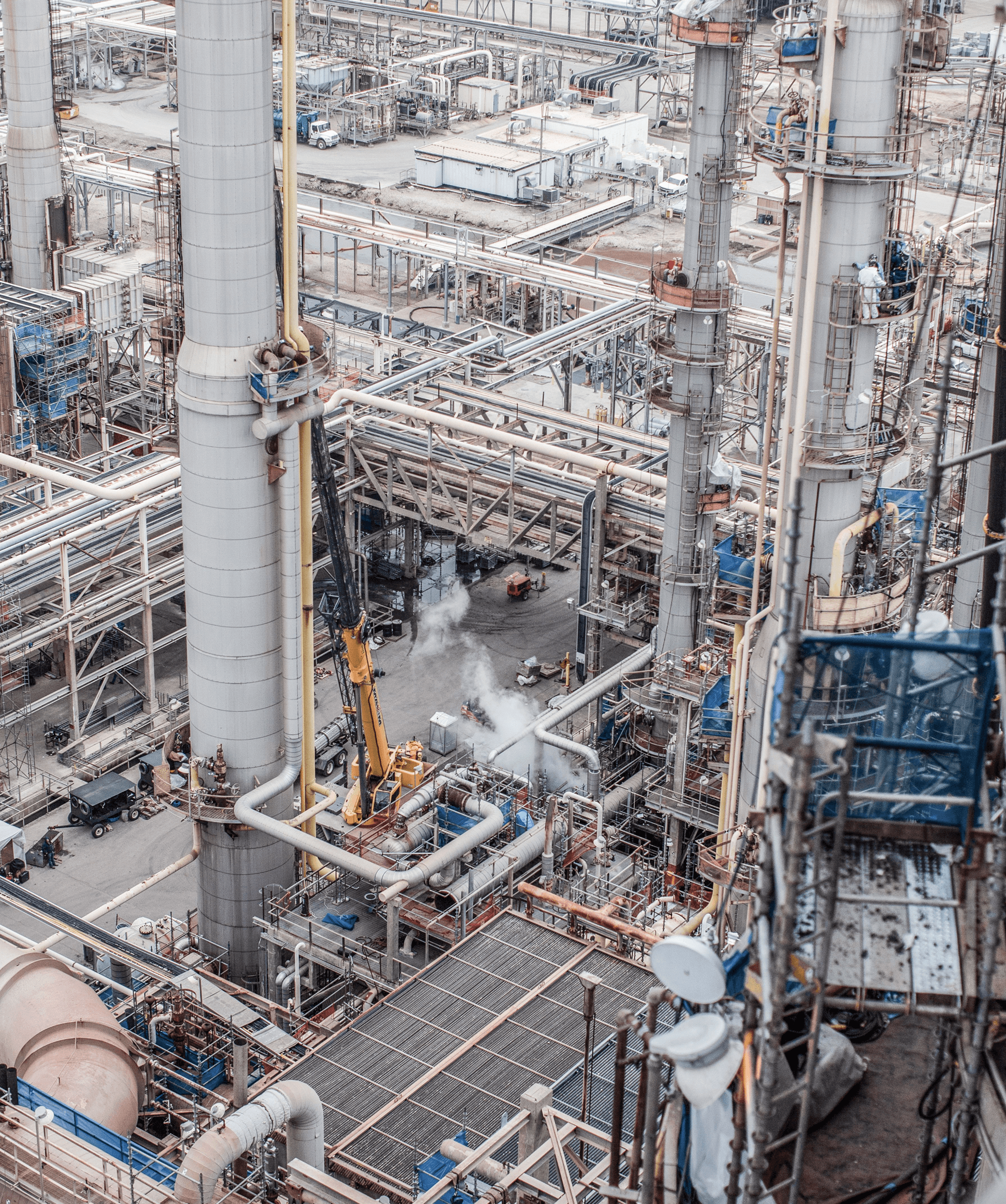

Towers

Specialty Tower Services for Safe Separation and Reliable Unit Throughput

Our tower teams focus on the vessels that drive separation and product quality in your units, including fractionation towers, distillation columns, drums, and reactors. We combine experienced supervisors, skilled welders, and purpose-built tooling to open, inspect, clean, and repair towers safely and efficiently.

From damaged trays and worn internals to pressure-boundary repairs and full tower revamps, we help you execute outage work that supports throughput, reliability, and mechanical integrity. The goal is straightforward: fewer leaks, fewer repeat entries, and towers that return to service ready to run.

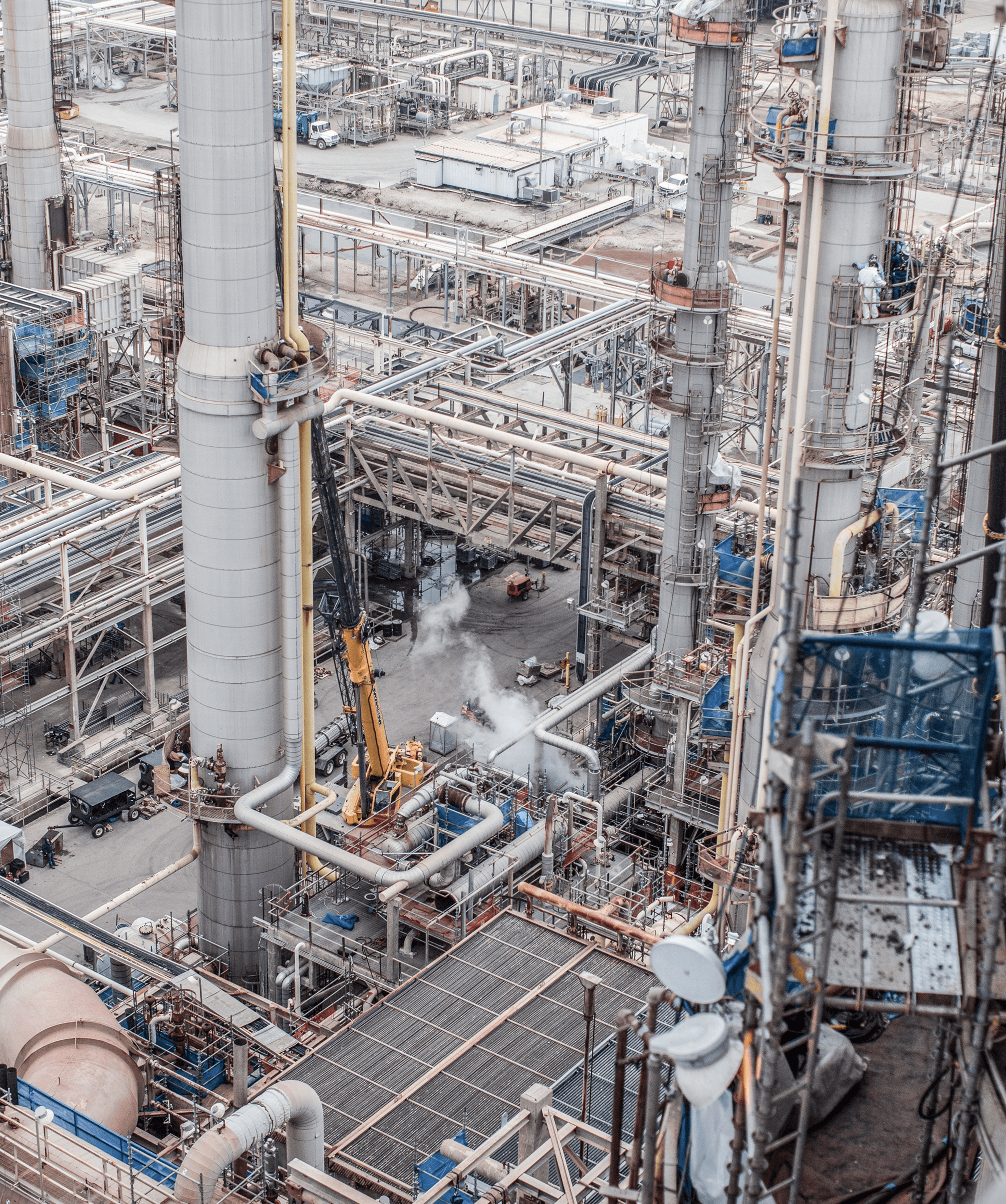

How We Execute Tower Outages and Revamps

For each outage, we align scope and sequencing with your inspection plans, internals vendors, and crane and rigging teams. Our crews plan access, lifts, and internal work paths so trays, packing, and attachments can be removed, replaced, or repaired with minimal lost time.

We use blind-to-blind workflows, controlled cleaning and repair steps, and disciplined QA/QC checks to manage each tower from open to close. That structure supports safer confined-space work, more predictable turnaround windows, and reliable performance once the tower is back online.

Key

Services

- Blind-to-blind outages

- Tower opening and cleaning

- Tray cleaning and repair

- In-place tray repairs

- Tray ring and attachments

- Packing removal and installs

- Packing change-outs, all materials

- Code welding on shells and nozzles

- Tower, drum, and reactor revamps

- Critical lift planning and support

- Flange bolt torquing and tensioning

- Vessel re-rate and design support

Applications

From blind-to-blind tower outages to targeted tray, packing, and nozzle repairs, our tower teams support turnarounds, revamps, and reliability programs across separation and mass-transfer equipment.

Industries

We Serve

Our tower services support

a wide range of sectors.

Why UPS Industrial?

One team, one trusted partner. From concept through maintenance or major turnaround, we provide end-to-end solutions.

We understand how to execute work safely while maximizing uptime, controlling costs, enhancing reliability, and driving operational excellence. That integration means fewer hand-offs, better coordination, faster execution, and fewer unknowns.

Let’s Talk About Your Tower Needs

Our tower services help improve tray performance, inspection access, and outage efficiency so towers come back online ready to run. Schedule a walkthrough or talk with our team about your next tower project or turnaround.